产品展示

产品展示

PRODUCT

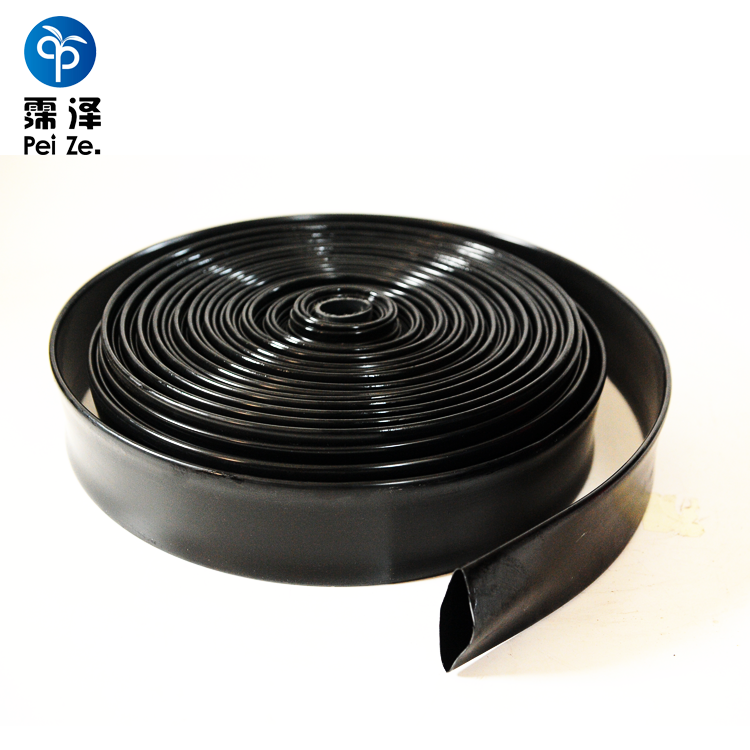

PE hose

PE软管采用聚乙烯材料制作而成,与PE硬管相比,管壁较薄,连接使用方便。成本造价较低,经济实用,现已被广泛的应用于农业灌溉。 PE hose is made of PE material. Compared with PE rigid pipe, the PE hose has a thin wall and can be connected and used conveniently. The cost of the product is low. It has been widely applied in agricultural irrigation. 产品型号参数:Φ50(壁厚0.8mm)、Φ63(壁厚0.6/0.8/1.2mm)、Φ75(壁厚1.2mm、1.3mm)、Φ90(壁厚1.2mm/1.6mm)。 Product models/ parameters: Φ50 (wall thickness 0.8mm), Φ63 (wall thickness 0.6/0.8/1.2mm), Φ75 (wall thickness 1.2mm, 1.3mm), Φ90 (wall thickness 1.2mm/1.6mm) . 产品特点: Product features: ①成本造价低,PE软管成本只有硬管的一半左右。 ②使用回收方便,柔韧性强,便于回收,且使用寿命长,性价比高。 ③配套管件齐全,安装使用方便快捷。 PE软管除了在微喷带连接中使用外,也可以用于滴灌带的连接,在大田微滴灌上应用极为广泛。 ① The product's cost is low. The cost of PE hose is only about one half of that of hard pipe. ② The product can be used and recycled conveniently. It is featured with strong flexibility, convenient recycling, long service life and high cost performance. ③ We provide a complete range of auxiliary pipe fittings, guaranteeing convenient and fast installation and use. Except for use in connection of micro sprinkling hoses, PE hose can also be used for connection of drip irrigation hoses, so it is applied in field micro drip irrigation very widely.

PE pipe

PE管是一款采用聚乙烯树脂为原材料,添加必要的辅助配料,经挤出加工而成的一种产品。 PE pipe is a product made of polyester resin and necessary auxiliary materials through extrusion processing. 产品型号:常用的PE管型号主要包括Φ16、Φ20、Φ25、Φ32、Φ40、Φ50、Φ63、Φ75、Φ90、Φ110等(一般管径较小的PE管为盘管)。根据管径及壁厚不同(壁厚1.0mm-7.0mm),其承压范围从0.32MPa-1.6MPa不等。产品特点:(PE管常用型号Φ16*1.0;Φ16*1.2;Φ20*1.5;Φ25*1.8;Φ32*2.0;Φ40*2.3;Φ50*3.0;Φ63*3.0;Φ63*3.5) Model: Commonly used PE pipe models mainly include Φ16, Φ20, Φ25, Φ32, Φ40, Φ50, Φ63, Φ75, Φ90, Φ110 and so on (usually PE pipe with a small pipe diameter is coil). According to the pipe diameter and the wall thickness (1.0mm-7.0mm), its pressure bearing scope ranges from 0.32MPa-1.6MPa. Product features: (commonly used PE pipe models Φ16*1.0; Φ16*1.2; Φ20*1.5; Φ25*1.8; Φ32*2.0; Φ40*2.3; Φ50*3.0; Φ63*3.0; Φ63*3.5) ①产品连接方便、施工简单,各种型号的锁紧管件齐全。PE管在安装完成后即可试水,使用方便; ②PE管具有良好的刚性、强度,也有很好的柔性;韧性、挠性好,断裂伸长率高,在不均匀沉降地区使用时效果极佳。 ③耐腐蚀、无需防腐处理,耐磨性能强,PE管正常使用寿命可达50年以上。 ④产品内壁光滑,流通能力大,水流阻力小,输水能力强,且产品成本低,性价比高。 ⑤低温抗冲击性好,聚乙烯的低温脆化温度极低,可在-20~40℃温度范围内安全使用。材料抗冲击性好,便于冬季安全使用,不会发生管子脆裂。 ① The product can be connected conveniently. Construction is simple. We provide a complete series of locking pipe fittings. After installation of PE pipe, water testing can be carried out. It is convenient to use. ②PE pipe is of good rigidity, strength, tenacity and flexibility as well as elongation at break. It can achieve superb effects in areas with uneven sedimentation. ③ The product is anti-corrosion and high abrasive resistance, separate anti-corrosion treatment is not needed. Thus the normal service life of PE pipe can be up to over 50 years. ④ The inner wall of the product is smooth, the flow capacity is large, the water flow resistance is small, the water delivery capacity is strong, the product cost is low, and the cost performance is high. ⑤ The product has good impact resistance performance at a low temperature. The low-temperature brittle point temperature of PE is extremely low. It can be used safely within -20~40℃. With good impact resistance performance, the product can be used safely in winter without brittle rupture of pipes. 产品应用范围:PE管目前广泛的应用于农业灌溉、城镇给排水、园林绿化管网等。 Application range of the product: PE pipe has been widely applied in agricultural irrigation, urban water supply and drainage, gardening pipeline, etc.

Fully-automatic fertilizer applicator

智能水肥一体机 三吸肥ZNC Intelligent water-fertilizer AIO three fertilizer sucking channels ZNC 智能施肥机YN-ZNF 1. 三通道施肥,通道单路250L/H 1.5KW stainless steel fertilization pump Manual partitioning 7 inch touch screen control Fertilizer sucking quantity adjusted manually 6. 三路肥料自动搅拌功能 7.肥料瞬时流量和累计流量显示 stantaneousnd accumulated flow display of fertilizer 三通道施肥,通道单路250L/H 2. 1.5KW不锈钢工业注肥泵 Rated fertilization pressure 8kg. 4. 注肥流量1.2方\H 3 Solenoid valve extension control function in the external area (256 channels extensible) 7. 自动混肥搅拌功能 Irrigation fertilization process extension 9. 水源水泵首部控制 10. 灌溉模式:分区循环、定时定量控制 Area-based circulation, timing and quantitative control. 11. 可以实时监测注肥总量和瞬时注肥量、实时监测工作电压 , 各类故障实时监测和报警功能. 可扩展气象站、土壤墒情、物联网平台等 可选配置Optional configuration 手机APP (包含三年服务费 ) 云平台连接手机端PC端Mobile APP (including three years of service fee), cloud platform connecting the mobile end and the PC end 自动混肥搅拌桶含搅拌电机+304不锈钢搅拌杆(化工级)500LAutomatic fertilizer mixing barrel, including mixing motor + 304 stainless steel mixing rod (chemical class) 500L

Adjustable red dripper

红色可调式滴头由两部分组成,上半部分是一个红色带有8孔出水口的旋转帽,下半部分是一个黑色带有外丝的承插接口。 The adjustable red dripper is composed of two parts. The upper part is a red turncap with eight water outlets. The lower part is a black socket (bell) and spigot joint with outer threads. 红色的旋转帽上有标注流量调节大小的方向,顺时针方向为调小出水流量的方向,逆时针方向是调大出水流量的方向。正常工作时喷洒半径:0-0.4m ;水量:0-70L每小时。 The red turncap carries a mark showing the flow size adjustment direction. The water flow will decrease by turning the turncap clockwise and will increase by turning it counterclockwise. The sprinkling radius during normal operation: 0-0.4m; Water yield: 0-70L per hour.

公司优势

公司优势

Why choose us

Water, fertilizer and labor saving

Water, fertilizer and labor saving

Drip irrigation belongs to whole pipeline water delivery and local micro irrigation, which reduces water leakage and loss. The drip irrigation system is only controlled manually or automatically through the valve and combined with fertilization, so it can save labor input and reduce production cost.

Control temperature and humidity

Control temperature and humidity

Drip irrigation belongs to local micro irrigation. Most of the soil surface remains dry, and the dripper evenly and slowly supplies water to the root soil layer, which can maintain and recover the ground temperature, reduce water evaporation and reduce indoor humidity.

Maintain soil structure

Maintain soil structure

Drip irrigation belongs to micro irrigation. Water infiltrates into the soil slowly and evenly, which can maintain the soil structure.

Improve quality, increase production and income

Improve quality, increase production and income

Because the application of drip irrigation reduces the application amount of water and fertilizer, pesticides and the occurrence of diseases and pests, it can improve the quality of products and advance the time to market.

Perfect design and construction

Perfect design and construction

Provide professional and perfect construction scheme and provide all-round one-stop service.

Hebei Runtian water-saving equipment Co., Ltd. located in Shijiazhuang, the capital of Hebei Province, provides customers with a series of complete sets of products and equipment such as drip irrigation system, drip irrigation belt and micro drip irrigation. At the same time, it can also provide design planning, budget preparation, production and supply of irrigation products, construction and installation of water-saving irrigation projects.

Hebei Runtian water-saving equipment Co., Ltd. located in Shijiazhuang, the capital of Hebei Province, provides customers with a series of complete sets of products and equipment such as drip irrigation system, drip irrigation belt and micro drip irrigation. At the same time, it can also provide design planning, budget preparation, production and supply of irrigation products, construction and installation of water-saving irrigation projects.

新闻中心

新闻中心

NEWS

2022-01

Installation of shed drip irrigation system

When drip irrigation is carried out in the shed, water outlets are generally set inside each shed. Devices such as filtration and fertilization can be connected from the water outlet. The following describes the connection of pipe fittings and equipment in detail. According to the area of greenhouse, reasonably divide the wheel irrigation group. Select a pipe with economic and reasonable pipe diameter on the basis of meeting irrigation water demand as the main pipe. First, install the head of the whole drip irrigation system. After the pipe (PE pipe) at one end of the water outlet, use a PE outer wire to lock and directly connect a PVC inner wire ball valve of the corresponding model. Because the PVC inner wire ball valve and Venturi fertilizer applicator are inner wire fittings, one iron pair of wires can be used to connect them. In order to ensure the tightness of the connection, an appropriate amount of raw material belt needs to be wound during the connection. The other side of the venturi fertilizer applicator is screwed and connected with the mesh filter (laminated filter) of the outer wire. Finally, the mesh (laminated) filter of the outer wire is locked and connected with the PE pipe through a PE inner wire locking straight through, and a complete set of head is installed. After the water transmission pipeline is connected from the head, the pipeline shall be arranged according to the irrigation zoning. In the greenhouse, PE pipe (or PVC pipe) can be selected as the water transmission pipeline. Generally, there is no trenching in the shed, and the pipeline is laid on the ground. The branch pipe generally adopts PE pipe or soft belt (convenient for drilling and connecting drip irrigation belt / pipe). The last is the installation of end emitters, commonly used as drip irrigation belt or drip irrigation pipe. For the shed with PE pipe as branch pipe and drip irrigation belt for drip irrigation, the corresponding model of punch shall be used first( Φ 16) Punch holes in the PE pipe, then install the upper pull ring bypass or reverse bus (positive bus) bypass, and then connect the drip irrigation belt with the bypass. Pipe fittings with valves can also be used, which is more convenient to control during use. The end of the drip irrigation belt can be connected with a pull ring plug, or a section of the drip irrigation belt can be cut. The end of the drip irrigation belt can be folded several times and stuffed into the cut drip irrigation belt, which makes the connection more convenient. 在大棚内的做滴灌时,一般每个大棚内部设有出水口。过滤施肥等装置便可从出水口进行连接。下面详细介绍一下管件器材连接情况。 根据大棚面积,合理的划分轮灌组。选择一种在能满足灌溉需水量的基础上,比较经济合理的管径的管材作为主管。 首先安装整套滴灌系统的首部,从出水口一端管(PE管)后,先使用一个PE外丝锁紧直通连接一个对应型号的PVC内丝球阀,因PVC内丝球阀与文丘里施肥器均为内丝管件,故可采用一铁对丝将其进行连接。为了保证连接的密封性,连接时需要缠绕适量的生料带。文丘里施肥器另一侧与外丝的网式过滤器(叠片式过滤器)进行拧紧连接。最后将外丝的网式(叠片式)过滤器通过一个PE内丝锁紧直通与PE管锁紧连接,一套完整的首部便完成了安装。 输水管道从首部连接出后,根据灌溉分区布置管道,大棚温室内,输水管可选用PE管(或PVC管均可),一般棚内不进行挖沟,管道铺设于地面。支管一般采用PE管或软带(便于打孔连接滴灌带/管)。 最后是末端灌水器的安装,常用的为滴灌带或滴灌管。对于采用PE管为支管、采用滴灌带进行滴灌的大棚,连接时先用相应型号的打孔器(Φ16)在PE管上打孔,然后安装上拉环旁通或反母(正母)旁通,然后将滴灌带与旁通连接,也可以采用带有阀门的管件,使用时更便于控制。滴灌带末端可以用拉环堵头连接,也可以剪断一段滴灌带,将滴灌带末端折叠几次后塞入剪断的滴灌带中,连接更为便捷。2022-01

Composition and installation mode of dropping arrow system

Drip arrows are often used for potted crops, and also for crops with frequent or uneven planting spacing (such as flowers). The pipeline layout is consistent with other irrigation systems, and the planting quantity and direction of crops need to be considered, so as to reasonably arrange the direction of main and branch pipes. The common dropping arrow system is mainly composed of water source, head hub (often equipped with water pump, check valve, gate valve, pressure gauge, flow meter, etc.), transmission and distribution water pipe network and end emitter dropping arrow, etc. Drip arrow belongs to a precision irrigation technology, which has high requirements on the water quality of the water source. It is generally necessary to install filters of suitable models when in use. The common ones are mainly centrifugal filters and mesh filters. If relatively clean groundwater is used, a filter with a small mesh number can be installed or no filter can be installed. For irrigation with river water, reservoir water or storage pool water, filters must be installed. At the same time, the combination of centrifugal filter and online filter is better. Combination and connection of dropping arrows: the common combination methods of dropping arrows are single arrow, one out two or one out four dropping arrows. Users can also choose long arrow, short arrow, straight arrow and curved arrow according to actual needs. A small tee or a small five-way is used as a connector in use Φ 3 capillary connection. In general, we use the dropping arrow in combination with the pressure compensated dripper to ensure double guarantee, so that the water from the dropping arrow is more stable and uniform. In this way, Φ 3. The capillary is connected with the pressure compensated emitter, and then Φ 3 punch holes on the capillary (commonly used) Φ 20 or Φ 16pe pipe), connect the pressure compensated emitter with the capillary orifice. Finally, insert the dropping arrow into the soil and fix it. After the annual irrigation, collect the dropping arrows, clean them and keep them properly for use when the next irrigation season comes. 滴箭常用于盆栽作物使用,也适用于作物种植间距经常改变或不均匀的作物(如花卉)。管道布置和其他灌溉系统一致,需要考虑作物种植数量、走向,从而合理的布置干、支管走向。 常见的滴箭系统主要有水源、首部枢纽(常配有水泵、逆止阀、闸阀、压力表、流量表等)、输配水管网及末端灌水器滴箭等几部分组成。 滴箭属于一种精度灌溉技术,对水源水质要求较高,使用时一般需要安装适应型号的过滤器,常见的主要有离心过滤器、网式过滤器。如采用较为洁净的地下水,可以安装目数较小的过滤器或不安装过滤器。对于采用河水、水库水或蓄水池水进行灌溉时,必须安装过滤器。同时采用离心式过滤器及网上过滤器组合效果更佳。 滴箭的组合连接:滴箭常用的组合方式有单箭、一出二式或一出四式滴箭。用户也可以根据实际需求选择长箭、短箭、直箭及弯箭。使用中采用小三通或小五通作为连接件,与Φ3毛管连接。通常使用时,我们采用滴箭与压力补偿式滴头配合使用,双重保障,这样滴箭出水更加稳定、均匀。采用此种方式时,Φ3毛管与压力补偿式滴头连接,然后采用Φ3打孔器在毛管上打孔(常用Φ20或Φ16PE管),将压力补偿式滴头与毛管孔口连接。最后,将滴箭箭头插入土中固定即可。待每年灌溉结束后,将滴箭收好,清洗干净后妥善保存,待下次灌溉季节来临时使用。2022-01

Eight misunderstandings in the use of drip irrigation systems. I don't know that these drip irr

Error 1: unreasonable irrigation system, drip irrigation flow is low, and users often can't see the irrigation process. If the irrigation time is too long, there will be deep leakage waste; If the irrigation time is too short, the root system will suffer from water stress. Understanding the irrigation intensity, plant water demand and soil field capacity of the irrigation system can better irrigate according to the needs of plants. At the same time, it should be borne in mind that the irrigation period and amount should be adjusted according to the climate and different growth stages of plants, and the same irrigation system cannot always be used. Error 2: the wrong dripper is adopted. The dripper is usually divided into two types: pressure compensated dripper and non pressure compensated dripper. Pressure compensation is more expensive, but the effect is better. First of all, the pressure compensation dripper can ensure that the water output of each dripper is uniform and the fertilization and irrigation are uniform. Secondly, some pressure compensated drippers can wash out the sundries blocking the dripper, and some pressure compensated drippers have large flow channels, which reduces the possibility of dripper blocking. Error 3: lack of filtration equipment. Many users mistakenly believe that well water does not need filtration. In fact, well water often contains coarse sand, fine sand and some chemicals to block the dripper. Common filters include screen filter, laminated filter and sand filter. If there is sand in the water, centrifugal filter should be used. Before installing the filtration system, analyze the physical and chemical composition of the water quality, adopt appropriate filtration facilities according to the water quality, and select the dripper with anti blocking performance. Error 4: there is no fertilization through the drip irrigation system. The simultaneous application of water and fertilizer is the biggest advantage of drip irrigation. The growth of plant roots is water and fertilizer oriented, and the application efficiency of fertilizer with irrigation water is the highest. However, when using the fertilization and irrigation system, there should be a device to prevent fertilizer backirrigation, so as to prevent fertilizer from polluting groundwater and other water sources. Error 5: lack of routine maintenance drip irrigation system needs careful maintenance to achieve optimal performance. Units with conditions shall often flush drip irrigation pipes to ensure smooth water flow of equipment. According to actual needs, periodic combined use of effective chemical treatment can be considered. Error 6: without pressure gauge and flow meter, these simple devices can help users "feel the pulse" of the irrigation system, so as to solve the problem of drip irrigation system that can not be accurately judged by the naked eye. Use a pressure gauge to detect the pressure at the head, middle and tail of the drip irrigation capillary, and compare the historical situation of the design pressure or water pressure to judge the problems of the drip irrigation system. The flowmeter can help users quickly judge the flow of water source. In addition, the flow data is helpful to calculate the actual flow and the historical flow of irrigation system. Error 7: mistakenly believe that all pipes are of the same quality. Different drip irrigation pipes have different raw material quality, production process and patented technology. More importantly, the dripper structure design of different brands of pipes is different. Drip irrigation pipes that can provide uniform water and fertilizer, have anti blocking performance, long service life and are easy to install and maintain should be selected. Error 8: ignoring the long-term operation cost, the drip irrigation system often needs to be used for more than ten or 20 years to irrigate millions of cubic meters of water and fertilizer, so it is very important to consider the uniformity of irrigation, the operation cost of pump station and daily maintenance cost. A well-designed system in the early stage can reduce the later operation cost through its good uniformity or energy saving. In addition, some suppliers have a lot of experience and know-how, which can guide users to select the correct irrigation system and provide help in the operation and maintenance of the system. 错误1:不合理的灌溉制度 滴灌流量低,使用者常常会看不到灌水过程,如果灌溉时间太长,则有会产生深层渗漏浪费;如果灌溉时间太短,根系又将发生水分胁迫。了解灌溉系统的灌水强度、植物需水量和土壤田间持水量,就能更好地根据植物需要进行灌溉。同时要铭记,灌溉周期和灌溉量要根据气候和植物的不同生长阶段而调整,不能始终采用同一灌溉制度。 错误2:采用错误的滴头 滴头通常分为两种型号,压力补偿式滴头和非压力补偿式。压力补偿式虽然贵一些,但效果更好。首先,压力补偿滴头可确保每一个滴头出水均匀,施肥灌溉均一。其次,部分压力补偿式滴头可将堵塞滴头的杂物洗出,还有一些压力补偿式滴头流道很大,减少了滴头堵塞的可能性。 错误3:缺少过滤设备 许多使用者错误的认为井水不需要过滤,而事实上井水经常含有粗砂、细砂和一些化学物质,堵塞滴头。常见的过滤器有网式过滤器、叠片过滤器和砂石过滤器,如果水中有砂则宜采用离心过滤器。在开始安装过滤系统前,要对水质的物理和化学组成进行分析,根据水质采用合适的过滤设施,并且选择具有抗堵塞性能的滴头。 错误4:没有通过滴灌系统进行施肥 水肥同步施入是滴灌的最大优点。植物根系生长具有向水、向肥性,肥料随灌溉水施用效率最高。但使用施肥灌溉系统要有防止肥料倒灌装置,以防肥料污染地下水和其他水源。 错误5:缺乏日常维护 滴灌系统需要通过精心维护以发挥最优性能。有条件的单位应经常冲洗滴灌管,保证设备水流的畅通。根据实际需要,可以考虑周期性配合使用有效的化学处理。 错误6:没有压力表和流量表 这些简单的设备可以帮助使用者给灌溉系统“把脉”,以解决凭肉眼无法准确判断的滴灌系统问题。用压力表检测滴灌管首部、中部和滴灌毛管尾部的压力情况,对比设计压力或水压的历史情况,可以判断滴灌系统的问题。流量计可以帮助使用者快速判断水源的流量,另外,流量数据有助于计算实际流量和灌溉系统的历史流量情况。 错误7:误认为所有的管品质一样 不同的滴灌管有不同的原材料品质、生产工艺和专利技术,更重要的是不同品牌管子的滴头结构设计是不同的。应该选择可以提供均匀水肥,具备抗阻塞性能,寿命长,易于安装和维护的滴灌管。 错误8:忽视长期运行费用 滴灌系统往往要使用十几年或20年以上,灌溉数百万立方的水肥,所以考虑灌溉的均匀度、泵站的运行费用以及日常维护费用非常重要。一个前期设计良好的系统,可通过其良好的均匀度或节能性降低后期运行成本。另外,一些供应商有很多经验和专有技术,可以指导使用者选用正确的灌溉系统,并在运行和维护系统方面提供帮助。